Brayton Cycle - Understanding Gas Turbine Engine in VR

In the sphere of thermodynamics cycles, the Brayton cycle process is an exemplar of advanced engineering.

This cycle, fundamental to the functionality of the modern gas turbine engine, serves as a beacon of the marvels of engineering. With the integration of VR, learners can now venture into an immersive journey, grasping the Brayton cycle working and its nuances in unparalleled detail.

Basics of the Brayton Cycle

Thermodynamics, the bedrock of many engineering marvels, introduces several cycles. Among these, the Brayton cycle process takes precedence due to its applicability in the gas turbine engine. Comprising three core stages:

● Compression: Initiating the Brayton cycle working, this process draws in and pressurizes air, setting the stage for subsequent actions.

● Combustion: A critical step where fuel integrates with the compressed air, undergoing combustion. This releases energy, raising the temperature of the now-supercharged air.

● Expansion: This is where work gets done. The hot, pressurized air propels through turbines, creating power before being released.

The Role of VR in Understanding Brayton Cycle

In the contemporary era, teaching turbofan jet engine mechanics has been revolutionized. The advent of the turbofan jet engine working model in VR has transformed conventional learning methods.

VR engineering makes the Brayton cycle process an interactive experience, transcending traditional boundaries in below mentioned ways:

☑️ Immersive Learning

One of the most promising facets of VR for fluid mechanics is the immersion it offers.

Beyond the traditional textbook diagrams and 2D animations, VR envelops learners in a dynamic, 3D world.

Immersive engineering in VR literally places them inside the Brayton cycle process. This isn't just viewing, but, it's experiencing. Within this environment, learners can witness the intricate dance of the Brayton cycle gas turbine working, understanding every stage from compression to exhaust in a holistic manner.

This form of immersive education leads to deeper understanding and retention.

☑️ Interactive 3D Visualization

VR goes beyond static learning.

Instead of passively observing, learners can interact.

With VR, learners have the liberty to dissect every segment of a gas turbine engine.

Want to see the intricate blades of the compressor? Zoom in.

Curious about the rapid-fire explosions in the combustion chamber? Slow it down.

This dynamic interaction makes the Brayton cycle process more than a concept. It becomes a tangible, manipulable entity.

☑️ Risk-Free Exploration

The beauty of VR engineering is the freedom it affords.

In the real world, mishandling a gas turbine engine can result in catastrophic consequences. However within the VR universe, learners can disassemble, tweak, and even purposely make errors to see the outcomes. For fields like aircraft maintenance engineering, this risk-free sandbox is priceless.

Trainees can gain hands-on experience, witness the results of mistakes, and refine their skills without ever endangering an actual aircraft.

Practical Applications of VR for Brayton Cycle Gas Turbine

The exploration of the Brayton cycle efficiency via conventional methods can be somewhat restricted due to the inherent limitations of traditional tools. However, with the integration of VR, we can bypass these constraints and venture into a virtual environment previously considered out of reach.

Asking how?

Here is the answer:

☑️ Real-world Scenarios and VR Simulations

The world of VR has unlocked avenues where theory meets practice.

Consider, for instance, a scenario where a learner, using VR, steps into a virtual hangar to diagnose a malfunctioning turbofan jet engine. As they don the VR headset, they are transported to an environment where every component of the engine, from the smallest bolt to the intricate combustion chamber, is visually and tangibly represented.

Well, of course, the beauty lies in the details. With VR, the students can:

● Zoom In and Out: This allows them to witness the Brayton cycle process at both a macro and micro level, ensuring a holistic and granulated understanding.

● Real-time Problem Solving: For a component malfunction, the VR environment can replicate the fault, letting the user troubleshoot in real-time, observing the impact of every rectification attempt on the Brayton cycle working.

● Scenario Variability: Beyond a single malfunction, VR can replicate multiple, diverse issues, including from minor inefficiencies to major breakdowns. This variety ensures learners are equipped to tackle an array of challenges, honing their problem-solving prowess.

☑️ Tailored Learning Paths

VR's adaptability ensures that the learning experience isn't one-size-fits-all. Recognizing that each learner is unique, VR labs have incorporated features ensuring a customized journey:

● Bookmark and Revisit: Complex segments of the Brayton cycle process can be marked and revisited, enabling reinforcement learning. If a learner grapples with the combustion phase, they can replay it, dissecting its nuances until clarity is achieved.

● Skip and Advance: Conversely, if a user is well-versed in a segment, say the compression phase, VR permits them to leapfrog to subsequent sections, ensuring that time isn't squandered on known concepts.

● Adaptive Challenges: As users master the Brayton cycle working, VR can ratchet up the complexity. From straightforward diagnostics to intricate, multifaceted problems, the VR environment evolves with the learner's proficiency, constantly challenging and sharpening their skills.

☑️ Collaborative Learning Environments

One of the often-overlooked marvels of VR is its collaborative potential.

Imagine learners from across the globe, each wearing a VR headset, collaborating in a virtual space to dissect and understand a gas turbine engine.

Together, they can discuss, deliberate, and deduce the Brayton cycle working, each bringing their unique perspective to the table. Such international collaboration not only deepens comprehension but fosters global networking, bridging geographical divides.

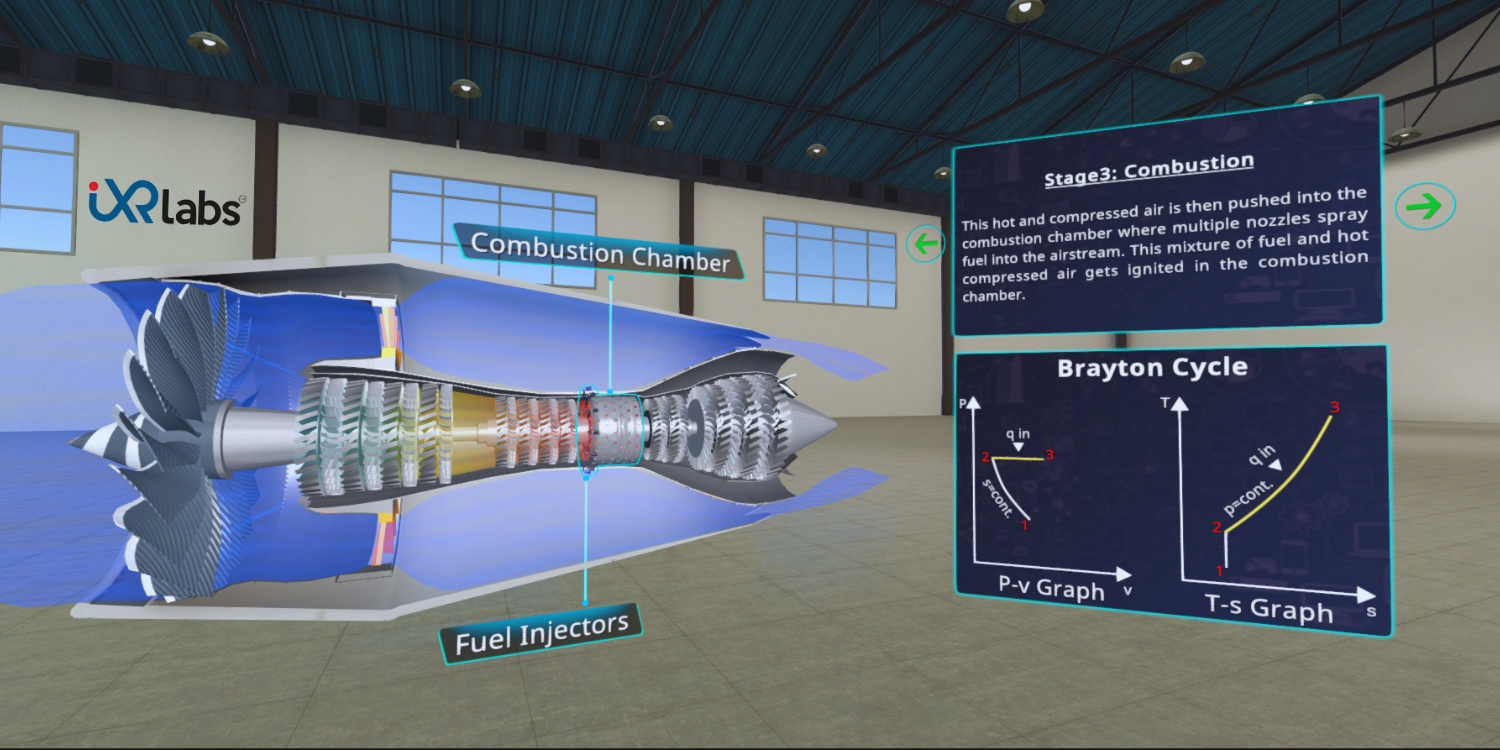

Understanding Brayton Cycle with iXR Labs

"Experience the power of immersion as iXRlabs brings the Brayton cycle to life in virtual reality."

"Experience the power of immersion as iXRlabs brings the Brayton cycle to life in virtual reality."

Features?

The features offered by iXR Labs to study the Brayton Cycle are explained in detail below:

☑️ X-ray View

Think of it as possessing the ability to see through materials, much like a medical X-ray but for machinery.

This means, that for our Brayton cycle process, learners can peer inside the compressor's dense structure or the combustion chamber's fiery core, observing internal components in action. This feature breaks down barriers and allows for an unprecedented understanding of hidden mechanisms.

☑️ Separate Parts View

Gas turbine engines are complex, with each component closely interacting with its neighbors.

With the 'Separate Parts' view, learners can isolate individual components, studying them in isolation before understanding their role within the larger system. This modular approach ensures that each section of the Brayton cycle process is understood in detail.

☑️ Show Working Feature

Perhaps the most exciting feature is the 'Show Working' capability.

Instead of a static display, this feature animates each component of the gas turbine engine. Learners can watch in real-time (or slow motion) how each part operates, from the air intake in the compressor to the exhaust's expulsion. This dynamic representation of the Brayton cycle working is a game-changer, providing clarity and fostering genuine understanding.

The inclusion of features like X-ray view, Separate Parts, and Show Working in the iXR Labs platforms is a testament to how far engineering education has come.

These technologically advanced tools, serve a simple purpose, thus, making complex concepts accessible and understandable. For learners navigating the Brayton cycle process, these tools don't just make learning easier, but, they make it enjoyable, fostering a genuine passion for the subject.

Future of VR in Engineering Education

The meteoric rise of VR in the pedagogical landscape, especially within the precincts of engineering, has thrown open doors to possibilities previously deemed fantastical. As we cast our eyes forward, it's evident that VR engineering is poised to revolutionize how future engineers are trained, and it's more than just a fleeting infatuation with technology.

The meteoric rise of VR in the pedagogical landscape, especially within the precincts of engineering, has thrown open doors to possibilities previously deemed fantastical. As we cast our eyes forward, it's evident that VR engineering is poised to revolutionize how future engineers are trained, and it's more than just a fleeting infatuation with technology.

☑️ Integrative Learning Systems

The seamless amalgamation of Augmented Reality (AR), Mixed Reality (MR), and Virtual Reality (VR), often termed Extended Reality (XR), promises an immersive ecosystem where boundaries between the physical and digital blur.

In such a domain, a student studying the Brayton cycle could manipulate virtual components while referencing real-world manuals, or superimpose simulations onto actual machinery for a juxtaposed comparison.

This isn't just learning, but it's living the learning.

☑️ Personalized AI-driven Curriculum

Imagine a VR curriculum tailored in real-time by AI algorithms gauging a student's proficiency, interests, and learning speed. As students navigate through concepts like gas propulsion cycle or Brayton cycle efficiency, the system could intuitively present challenges, quizzes, or supplementary resources calibrated to the individual's needs, ensuring a learning curve that's neither too steep nor too flat.

☑️ Haptic Feedback Systems

The world of VR is transcending the visual. Tomorrow's VR labs might be equipped with haptic feedback systems.

Such advancements would allow students to 'feel' the machinery. Whether it's the vibration of a compressor, the heat from a combustion chamber, or the flow of air in a gas turbine engine, this tactile dimension could vastly enhance comprehension and retention.

☑️ Global Collaborative Platforms

Building upon the collaborative potential of VR, we might soon witness global engineering hubs in the virtual space.

Students and professionals from across continents could converge in virtual auditoriums, workshops, or labs, sharing knowledge, collaborating on projects, or brainstorming innovations. Such platforms would not only democratize education, ensuring expertise isn't geographically siloed but would foster a global community of engineering aficionados.

☑️ Environmental and Economic Benefits

Traditional engineering labs, with their vast machinery, consume space, resources, and power. Virtual labs, replicating the same machinery in the digital domain, drastically reduce the environmental footprint.

The benefits of VR labs doesn’t stop here.

The VR labs present an economically viable alternative, slashing the costs associated with procuring, maintaining, and updating heavy machinery.

☑️ Immersive Assessments

The future might also reshape how engineering assessments are conducted. Instead of paper-based tests or rudimentary practicals, students could be placed in virtual scenarios - say, an aircraft maintenance crisis or a malfunctioning turbofan jet engine working model in VR.

Their response, problem-solving aptitude, and practical application of the Brayton cycle process could offer a more holistic measure of their proficiency than traditional exams.

☑️ Endless Expansion

The dynamic nature of VR means that as the field of engineering evolves, so will the virtual curriculum. New discoveries, updated methods, or emerging technologies can be incorporated with ease, ensuring that the VR-based engineering syllabus remains at the cutting edge, always.

Wrapping Up

It's clear that the Brayton cycle stands as a cornerstone of modern engineering understanding, serving as a symbol of the intricate dance between science, innovation, and application.

However, the metamorphosis of how we learn about such processes, from 2D diagrams to interactive 3D VR experiences, is a testament to human ingenuity and adaptability.

Today, we are not just passively learning, but, we are immersing, interacting, and innovating.

iXR Labs, with its groundbreaking features, epitomizes this shift in pedagogy, making it evident that the future of engineering education is not just about mastering content, but about experiencing it.

As we stand at this juncture, it's important to appreciate and acknowledge every educator, developer, and learner who has embraced this paradigm shift. Their combined efforts are not merely paving the way for a brighter, more inclusive educational horizon, but they are redefining the very essence of understanding and knowledge acquisition.