Virtual Reality Tensile Test Machines: Amping Up Material Sciences

Virtual labs have played an important part in disregarding expensive laboratory equipments. The technology also plays a part in the effective and safe train engineering students.

• Allied Market Research has predicted that the simulated labs and virtual training market will reach a value of $601.85 Billion in 2027.

• The previous valuation was at $204.41 Billion in 2019.

• The market will also experience a CAGR of 13.7% from 2020 to 2027.

This gigantic growth will be fuelled by the following advantages:

• Expanding access to labs.

• Better training method through interactive elements.

• A safe environment to play with the variables and analyze the outcomes.

• Cost efficiency.

• Piquing interest in the new generation of learners through a tech-centric approach.

To understand how these advantages will pan out in a real-life teaching scenario, here we will analyze the application of one such element within a virtual lab: Tensile Testing Machines.

Tensile Testing Machines

These machines, often referred to as pull tester or UTM sports an electromagnetic mechanism to understand the tensile force and deformation behavior of a material.

This learning can then be applied to understand Young’s modulus, yield strength, strain hardening, and Poisson’s ration characteristics of the said material.

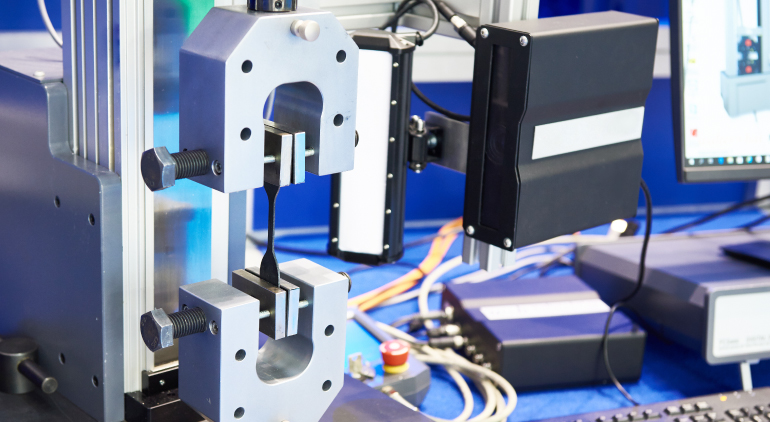

Until now, the most common machine is the ASTM D638. The challenges with using a traditional tester include:

• Alignment of the specimen to be tested.

• Using a wrong grip, axial misalignment.

• Wrong load cell capacity.

• Defective edges of the material.

Any of these mistakes would cost time and resources to the learner. And this can only be averted through repeated, consequence-free training.

With virtual tensile testing machines, these challenges become simple parameters to experiment with. Without causing any physical harm, the student can get to understand the rights and wrongs of tensile testing. Let us take a look at the intricate workings of a virtual tensile tester.

Virtual Tensile Testing Machines

Technical Environment with Virtual Tensile Tester

The virtual tensile testing machine is written in Java and C++ along with Net Beans 5.5. The additional application such as chart transformation is compiled through Borland C++ Builder 6.0. The simulation is based on the actual machine, Zwick Z100.

Samples Included

There are 10 materials that can be sampled on the machine. This includes steels, alumina, and copper alloys like:

• 16MnCr5

• X30Cr13

• X5CrNi18-10

• X20CrNi172

• S235JR

• BSt500S

• Al-Pa6 Ta

• Cu-ETP

• CuZn40Pb2

• AlSi9Mg

• MgAl92N1

The first 8 materials can be tested for tensile strength and compression, the 9th only for tensile strength and the last one only for compression. The European Standard PN-EN 10002-1:2004 sample dimensions are applied to all the samples.

The Program

The interface of the program is user friendly and sports a step by step approach to tensile strength testing. Similar to an actual machine, the simulation starts with calibration.

Then the student will be guided to put the sample into the machine. After locking the handles, the student needs to start the compression or tensile test.

An additional attraction is the inclusion of sound that adds to the realism. All the sounds have been recorded on the actual machine.

As the material changes dimensions during the test, a chart-based output is generated to project the rupture as well as the strength parameters of the material.

The Back-end

There are 26 Java classes implemented to actualize this simulation. This includes classes for drawings, classes to read xml data into the simulation’s memory, and some for playing the sounds.

One primary requirement is the proper allocation of tags for the file structure to be appropriately read and executed. Some examples of tags are:

•

•

•

•

All these tags can be edited using a simple text editor.

From the above discussion, we see how easy it is to add a tensile tester to your virtual labs. The ease is complemented with a plethora of advantages that addresses the challenges that was discussed. So what can we conclude from this?

Read More : Virtual Reality in Engineering Education

Conclusion

Virtual labs can complement the traditional ones, especially in a teaching environment. Equipment damage can be greatly reduced by making the students undergo the virtual training first before getting into the actual machine.

The virtual machine that we discussed here requires Java Virtual Machine software and a computer.

Many major players within the industry such as McGraw Hill, Pearson, Mcmillan, and John Wiley Learning have already tried to incorporate virtual labs to their educational provision.

When it comes to virtual tensile testing lab, Silesian University of technology has integrated a virtual tensile tester to their Material Sciences Virtual Laboratory.

The future of the tech lies in its benefits for both institutions and individual learners through remote or virtual lab applications.

At iXR Labs, we engage learners with enhanced, exciting and efficient higher education content powered by virtual reality.

To know more about iXR Labs or to gain insights into the higher education industry, check out www.ixrlabs.com .